當(dāng)前位置:首頁 > 資訊 > 企業(yè)新聞 >

迪拜聯(lián)合預(yù)制混凝土公司(United Precast Concrete Dubai,簡(jiǎn)稱:UPC迪拜)成立25年來,幾乎參與了該地區(qū)所有大型建筑項(xiàng)目,極大助力該地區(qū)建筑風(fēng)景線的塑造。

In the 25 years since it was first established, United Precast Concrete Dubai has taken part in almost all major construction projects in the region, helping in shaping the region’s landscape.

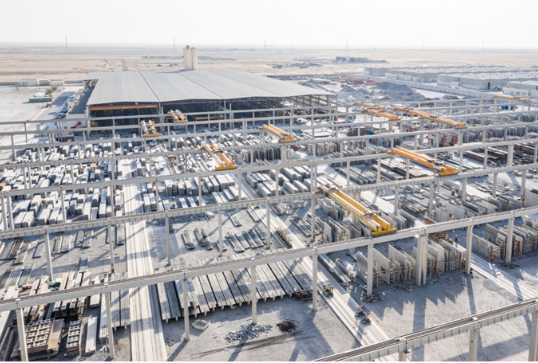

南非土木工程師里克特·克魯格(Rickert Kruger)在過去三年中,一直擔(dān)任UPC迪拜的助理生產(chǎn)經(jīng)理。克魯格在該公司的迪拜工業(yè)城(Dubai Industrial City ,DIC)工廠工作,該工廠是這一地區(qū)最大的預(yù)制工廠之一。這座由Elematic設(shè)計(jì)的,最初完全用于生產(chǎn)預(yù)制混凝土空心樓板的工廠,建造于20. 5萬平方米的生產(chǎn)基地內(nèi)。目前,工廠分三班制運(yùn)作,每天利用翻轉(zhuǎn)臺(tái)模可生產(chǎn)多達(dá)400立方米的構(gòu)件,和2000平方米的空心樓板構(gòu)件。

South African civil engineer Rickert Kruger has been an Assistant Production Manager at United Precast Concrete (UPC) Dubai for the past three years. Kruger works at the company’s Dubai Industrial City (DIC) plant, which is one of the largest in the region. Built on a 205 000 sq m property, the factory was originally designed by Elematic as a 100 percent hollow core factory. The plant, which runs three shifts, can produce up to 400 m3 of tilt products and 2000 m2 of hollow core per day.

克魯格對(duì)于生產(chǎn)過程中的挑戰(zhàn)了如指掌。“去年,我們?cè)诖蠹s有7天的時(shí)間出現(xiàn)了鋼絞線滑移問題。幸運(yùn)的是,我們得到了Elematic的快速響應(yīng):他們的團(tuán)隊(duì)在一周內(nèi)就飛過來幫助我們解決了問題。他們不僅檢查了產(chǎn)品,還檢查了脫模劑和鋼絞線設(shè)備的校準(zhǔn),以及所有其它可能出錯(cuò)的地方。Elematic用實(shí)際行動(dòng)為我們提供技術(shù)支持,我們非常感激,同時(shí)這也是我們所期待的。”他回憶道。

Kruger is no stranger to challenges during production. “Last year, we had about seven days of strand slippages occur. Fortunately, we were able to get a fast response from Elematic: their team flew in within a week and helped us fix the situation. They looked not only into the products but also into the release agents, the calibration of the strand equipment. All the variables that could have gone wrong. This is the kind of hands-on technical problem solving that we’ve come to appreciate and expect from Elematic,” he recalls.

Elematic供應(yīng)了UPC迪拜DIC工廠90%以上的設(shè)備。“我們有超過2公里的混凝土穿梭運(yùn)輸機(jī)軌道,10臺(tái)混凝土穿梭運(yùn)輸機(jī),18臺(tái)擠出機(jī),6臺(tái)混凝土分配機(jī),以及8臺(tái)切割鋸。當(dāng)我們決定將翻轉(zhuǎn)臺(tái)模產(chǎn)品也列為我們的供貨范圍時(shí),我們遇到了一些挑戰(zhàn),因?yàn)槎褕?chǎng)的位置與工廠成垂直90°,但是這個(gè)問題最終也得到了令人滿意的解決。” Kruger解釋說。

Elematic supplies over 90 percent of the equipment in UPC Dubai’s DIC plant. “We have over 2 km of tracking shuttle, 10 shuttles, 18 extruder units, 6 dispatcher units and 8 cutting machines. We faced some challenges when we decided to include tilt products in our offering because the stockyard was set up 90° perpendicular to the factory, but that issue was solved satisfactorily as well,” Kruger explains.

“我們的混凝土供應(yīng)是通過穿梭機(jī)運(yùn)送至皮帶式澆筑設(shè)備中,并運(yùn)至我們4個(gè)生產(chǎn)車間。 Elematic系統(tǒng)允許將混凝土運(yùn)輸?shù)饺魏诬囬g,也能從一個(gè)車間轉(zhuǎn)移到另一個(gè)車間,這增加了我們的靈活性。” 他補(bǔ)充道。”O(jiān)ur concrete supply is transported through shuttles into concrete dispatching machines to the 12 stockyard bays and 4 production bays we have. The Elematic system allows concrete to be transported to into any bay, we’re able to move from one bay to another, which gives us a lot of versatility,” he adds.

“Elematic交付的機(jī)器非常耐用,有些機(jī)器甚至已經(jīng)運(yùn)行了25年以上。它們也非常易于操作,就像我們有一次,操作員因?yàn)樘厥庠驔]有出現(xiàn),當(dāng)時(shí)一位沒有使用過該設(shè)備的生產(chǎn)工程師,在操作員不在場(chǎng)的緊急情況下成功操縱了攪拌站。”

“The Elematic machines we are using are exceptionally durable; some have been in operation for over 25 years. They’re also very user-friendly. We had an incident when a Production Engineer, who had no prior experience using the equipment, was able to operate the batch plant in an emergency when the operator wasn’t present.”

利用預(yù)制技術(shù)實(shí)現(xiàn)成本節(jié)約

Precast use translates to savings

在迪拜,最常見的建筑施工技術(shù)是現(xiàn)場(chǎng)澆筑。而高級(jí)項(xiàng)目經(jīng)理伊讓那·東立特(Iranna Dongritot)指出,相較于此,預(yù)制混凝土技術(shù)則具有更多的優(yōu)勢(shì)。

In Dubai, the most common construction technique is to cast in situ. Iranna Dongritot, Senior Projects Manager, points out that precast concrete offers a lot of benefits compared to this.

“使用預(yù)制件比現(xiàn)場(chǎng)澆筑的速度快40%到50%。 當(dāng)然,由于運(yùn)輸和起重機(jī)等成本,它的確要多出5%到6%的費(fèi)用,但是如果將時(shí)間轉(zhuǎn)換為成本,其實(shí)選擇預(yù)制件會(huì)更便宜。節(jié)省的時(shí)間可以轉(zhuǎn)化為項(xiàng)目價(jià)值的整體節(jié)省,并將為業(yè)主帶來盡早的租金收入。” 東立特說。

“Construction using precast is about 40 to 50 percent faster than casting in situ. It does cost about 5 to 6 percent more because of transportation and crane costs, but if you convert time in to cost, precast is cheaper. This time saving converts to overall savings in project value and will give early rental income to the owners,” Dongritot says.

東立特還指出,建筑的維護(hù)成本也可以通過使用預(yù)制混凝土技術(shù)而得以避免。“例如,現(xiàn)場(chǎng)澆筑的建筑物每三到四年就需要進(jìn)行維護(hù),重新粉刷或修復(fù)裂縫。而混凝土預(yù)制件的維護(hù)成本則很低,甚至可以忽略不計(jì),如果你使用的是彩色混凝土,那么在建筑物的整個(gè)使用壽命周期內(nèi)都不需要重新粉刷。”

Dongritot also points to the maintenance costs that could be avoided by using precast. “A building cast in situ would need maintenance every three to four years, to repaint or to fix cracks, for example. Precast, on the other hand, is very low maintenance, needing even negligible maintenance and if you use colored concrete, you don’t need to repaint the building during its lifetime.”

安全性是選擇預(yù)制件的另一個(gè)很好的理由。 “在建筑中使用預(yù)制件意味著更少的安全隱患,因?yàn)楝F(xiàn)場(chǎng)所需的人員更少。并且所有產(chǎn)品都是在可控的質(zhì)量環(huán)境中生產(chǎn)的,因此交付的構(gòu)件均符合生產(chǎn)規(guī)范。預(yù)制件的強(qiáng)度也總是比現(xiàn)場(chǎng)澆筑或砌塊的強(qiáng)度更高。”他指出。

Safety is another good reason to choose precast. “Using precast in construction means less safety hazards and headaches as less people are needed on site. And because everything is produced in a controlled quality environment, all the elements are always delivered according to specifications. Precast is also always of higher strength than in situ or block work,” he points out.

遍布阿聯(lián)酋的預(yù)制建筑項(xiàng)目

Projects across the UAE

UPC迪拜為阿聯(lián)酋的大型建筑項(xiàng)目做出了卓越貢獻(xiàn),例如,為阿拉伯塔朱美拉酒店(Burj al Arab)提供預(yù)制件、旋轉(zhuǎn)樓梯和空心樓板,為全預(yù)制的宜家迪拜節(jié)日城(Ikea Dubai Festival City)提供預(yù)制構(gòu)件,以及向迪拜節(jié)日廣場(chǎng)(Dubai Festival Plaza)提供了大約111,000平方米預(yù)制空心樓板、梁和柱等。

UPC Dubai has contributed to major construction projects in the UAE, supplying precast, spiral staircases and hollow core to the Burj al Arab hotel in Jumeirah, the fully precast Ikea Dubai Festival City and providing about 111 000 m2 hollow core slabs with columns and beam structures for the Dubai Festival Plaza mall.

馬修·帕爾默(Matthew Palmer)說:“我們的愿景是通過成為該地區(qū)的領(lǐng)先的預(yù)制構(gòu)件供應(yīng)商,使預(yù)制混凝土有所作為。” 馬修·帕爾默于15年前在UPC Dubai擔(dān)任項(xiàng)目經(jīng)理,現(xiàn)在是該公司的總經(jīng)理。

“Our vision is to make a difference with precast by being the leading precaster in the region,” says Matthew Palmer, who started with UPC Dubai 15 years ago as a project manager and is now the company’s General Manager.

他對(duì)公司的貢獻(xiàn)包括,例如位于魯韋斯(Ruwais)的阿布扎比國家石油公司(ADNOC)設(shè)施擴(kuò)建等項(xiàng)目,和確保UPC迪拜對(duì)項(xiàng)目的準(zhǔn)時(shí)交付、產(chǎn)品質(zhì)量,以及創(chuàng)建能為客戶提供良好交流平臺(tái)的項(xiàng)目管理團(tuán)隊(duì)。

He attributes the company’s successful contributions to projects such as the extension of some facilities of the Abu Dhabi National Oil Company (ADNOC) in Ruwais to UPC Dubai’s on-time delivery, product quality and a project management team that offers a good interface with client.

“對(duì)于那些正在籌備建立自己的預(yù)制工廠的公司,我覺得他們應(yīng)確保所建造的工廠有足夠的空間,其次是具備擴(kuò)建的可能性。在我們的DIC工廠中,我們的設(shè)備能夠制造預(yù)應(yīng)力空心樓板及利用翻轉(zhuǎn)臺(tái)模生產(chǎn)的構(gòu)件。當(dāng)然,一個(gè)好的工廠位置也尤其重要。”

“Companies looking to start their own precast production facility should ensure that the factory they are building has good capacity and offers possibilities for expansion. In our DIC plant, for example, the equipment we have allows us to manufacture hollow core to prestressed to tilt items. A good location is, of course, also important.”

他回憶說, 25年前UPC公司在迪拜剛成立時(shí),真的是從零開始,他們得不斷地向人們解釋什么是預(yù)制件,什么是預(yù)制混凝土空心樓板技術(shù)。“預(yù)制件在阿聯(lián)酋已經(jīng)走了很長一段路。它現(xiàn)在已經(jīng)成為建造別墅和其他住宅項(xiàng)目的首選方案,但我覺得預(yù)制技術(shù)仍有很大的發(fā)展空間。”

He recalls that when UPC started in Dubai 25 years ago, they had to start from scratch, by explaining to people what precast, especially hollow core technology, was. “Precast has come a long way in the UAE. It’s become the preferred solution for building villas and other residential projects, but there is still is a lot of room to develop.”

帕爾默對(duì)Elematic自始至終為工廠的啟動(dòng)和運(yùn)營提供支持表示贊賞。“從我們的攪拌站到混凝土分配再到澆筑機(jī),整個(gè)工廠都運(yùn)行著Elematic的設(shè)備。Elematic設(shè)備的耐用性和性能得到了充分的測(cè)試。服務(wù)水平是無與倫比的,機(jī)器的質(zhì)量也經(jīng)受住了時(shí)間的考驗(yàn)。”

Palmer credits Elematic with helping the factory get up and running. “From our batching plants to concrete distribution to casting machines, the whole factory runs with Elematic. The durability and performance of Elematic machines are well-tested. The level of service is unparalleled and the quality of the machines has stood the test of time.”

“我們對(duì)Elematic感到非常滿意的一點(diǎn)是他們的售后服務(wù)。這對(duì)我們的幫助非常大,因?yàn)樵谥袞|,地方當(dāng)局不斷引入新規(guī)定,因此我們也必須不斷地更新設(shè)備。Elematic為我們提供了很好的建議,以及實(shí)現(xiàn)這些目標(biāo)的方案。他們幫助我們解決了從舊項(xiàng)目到新項(xiàng)目的幾乎所有問題。當(dāng)我們需要他們時(shí),總是能夠從對(duì)的人那里獲得對(duì)的幫助。” 帕爾默總結(jié)說。

“One thing we’re very happy with Elematic is their after sales service. This is especially helpful because in the Middle East, local authorities are always introducing new regulations, so we constantly have to update our equipment. Elematic gives us good feedback about what needs to be done to make this happen. They help us with any issues we might have, from problem solving to new projects. We always have access to the correct people when we need them,” he concludes.

UPC迪拜概覽

UPC Dubai box

UPC迪拜于25年前開始運(yùn)營,是該地區(qū)預(yù)制混凝土空心樓板技術(shù)的開拓者之一。

UPC Dubai started its operations 25 years ago and is one of the pioneers of hollow core technology in the region.

聯(lián)合預(yù)制混凝土DIC工廠

United Precast Concrete DIC Factory

成立年份:2009年

年平均產(chǎn)量:13萬立方米翻轉(zhuǎn)構(gòu)件; 75萬平方米空心樓板

工廠生產(chǎn)面積:24,000 平方米

堆場(chǎng)面積:96,000 平方米

總面積:20.5萬平方米

Year established: 2009

Average annual production: 130 000 m3 tilt elements; 750 000 m2 hollow core slabs

Factory production size: 24 000 m2

Stock year area: 96 000 m2

Total factory area: 205 000 m2

項(xiàng)目重點(diǎn):

項(xiàng)目:底層 + 4層(G + 4)員工宿舍大樓

地點(diǎn):阿聯(lián)酋迪拜杰貝阿里(Jabel Ali)工業(yè)區(qū)

規(guī)格:底層 + 4層(一個(gè)結(jié)構(gòu)),可停放10輛巴士

建筑面積:約6,500 平方米

容量:650至700人

用途:?jiǎn)T工住宿

建造年份:2019

預(yù)制設(shè)計(jì):迪拜聯(lián)合預(yù)制

所使用的預(yù)制混凝土構(gòu)件:帶保溫墻板/承重墻板/梁/樓梯/女兒墻,共529件,空心樓板-5600m2

Project highlights:

Project name: G+4 Labor accommodation

Location: Jabel Ali Industrial Area, Dubai, UAE

Size: G+4 (one structure) with parking for 10 buses

Built-up area: about 6 500 m2

Capacity: 650 to 700 people

Purpose: Labor accommodation

Year of construction: 2019

Precast Design: United Precast Dubai

Precast elements used: Insulated wall panels/ load bearing panels/Beams/Staircases/Parapets – 529 nos. & Hollow core slabs—5600m2

項(xiàng)目選擇了預(yù)制混凝土技術(shù),以節(jié)省時(shí)間、成本并減少現(xiàn)場(chǎng)的人力。與傳統(tǒng)現(xiàn)澆的施工方法相比,預(yù)制技術(shù)還具有更好的質(zhì)量水平,并在建筑物的使用壽命內(nèi)有效降低維護(hù)成本,因此預(yù)制技術(shù)也是我們的首選。所有結(jié)構(gòu)構(gòu)件均為預(yù)制件,內(nèi)墻采用砌塊和抹灰。員工宿舍大樓的白色外墻帶有頗具挑戰(zhàn)的灰色噴砂處理。

Precast was chosen for the project to save time and costs as well as to reduce manpower at site. It was also preferred for the better level of quality compared to traditional construction methods and to reduce maintenance costs over the building’s lifetime. All structural elements are precast and internal walls are done in block work and plaster. The labor accommodation features white external panels with a gray sandblast finish, which was a challenge.

左起:馬修·帕爾默,南非土木工程師、UPC助理生產(chǎn)經(jīng)理

林德羅斯·柯特,Elematic區(qū)域銷售總監(jiān)

里克特·克魯格, UPC總經(jīng)理

(編輯:奚雅青)

延伸閱讀:

混凝土“打印工廠”上新!國內(nèi)最高智能化水平梯枕生產(chǎn)線正式投產(chǎn) 中交二航局自主研發(fā)一體化智能筑塔機(jī) 大截面SPCS空腔墻、空腔柱在高層產(chǎn)業(yè)園項(xiàng)目的大規(guī)模應(yīng)用(1) 凡本網(wǎng)注明“來源:預(yù)制建筑網(wǎng)”的所有資料版權(quán)均為預(yù)制建筑網(wǎng)獨(dú)家所有,任何媒體、網(wǎng)站或個(gè)人在轉(zhuǎn)載使用時(shí)必須注明來源“預(yù)制建筑網(wǎng)”,違反者本網(wǎng)將依法追究責(zé)任。 (2) 本網(wǎng)轉(zhuǎn)載并注明其他來源的稿件,是本著為讀者傳遞更多信息之目的,并不意味著贊同其觀點(diǎn)或證實(shí)其內(nèi)容的真實(shí)性,請(qǐng)讀者僅作參考,并請(qǐng)自行核實(shí)相關(guān)內(nèi)容。其他媒體、網(wǎng)站或個(gè)人從本網(wǎng)轉(zhuǎn)載使用時(shí),必須保留本網(wǎng)注明的稿件來源,禁止擅自篡改稿件來源,并自負(fù)版權(quán)等法律責(zé)任,違反者本網(wǎng)也將依法追究責(zé)任。 (3) 如本網(wǎng)轉(zhuǎn)載稿涉及版權(quán)等問題,請(qǐng)作者一周內(nèi)書面來函聯(lián)系。